|

Art

Steve...

Bowls

'In

Progress'

Photo Archive

Instruments

Spoons

Bio

Sue...

Watercolors

Fingerweaving

Boxes

Bio

How to Order

Contact Us

|

Stewart-MacDonald Tools & Tool Ideas

by Steve Schmeck

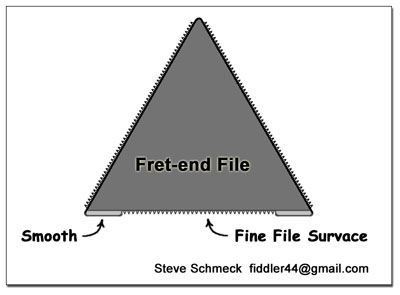

First, an idea for a new tool I'd like to see someone make.

Here is what I used on my most recent re-fret job to level and give

preliminary shape to the fret ends:

Your basic triangular file with painter's tape protecting the edges

- leaving an effective, safe cutting surface preventing

damage to the edges of the fingerboard.

Here is a drawing of the proposed tool:

Stewart MacDonald, please make these! Thanks.

And on

another subject, this is my current favorite vise for working on

carvings...

|

|

|

This vise has worked great! It has proved to be

super-strong, quiet (no rattles) and easy and quick to use.

With a

quarter-turn of the round knob the work can be rotated 360

degrees and with another quick turn, locked securely. A flip

of the tilt-locking lever and the vise can be tilted from

horizontal to nearly vertical. When tilted the bowl hangs

out over the edge of the bench and I can easily access the

back/bottom of a carving.

Below I've

described the fairly straight-forward modifications I've

made to this vise. |

|

The Carving

Process...

|