|

Scarfing (Joining two pieces of wood using tapered joints and epoxy as glue) |

|

Here I'm ripping the first of the stringers. I used a Skillsaw and a nice new (sharp) thin-kerf blade. Very little waste because of the thin blade and the stringers are nearly planer smooth. |

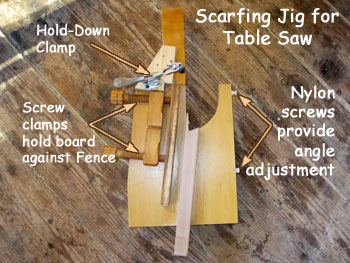

This is my version of a scarfing jig. It cranked out about 40 very good joints at two cuts per joint for the dory, and a bunch more for the kayaks. The nylon (license plate screws & nuts) adjusters on the right ride smoothly along the table saw fence and allow the jig to cut from about 6:1 to 12:1 cuts. This setting produced approx. 9:1 scarfs. |

|

|

|

The jig in action. My hand isn't as close to that blade as it looks. A very stable and predictable device. The process isn't real fast as I shut the saw off between cuts to both set up for the next cut and clear away the small wedge that is left. This isn't your fancy table saw; my Dad bought this Shopsmith back in the early 50's and it has served flawlessly for over 60 years! |

And here are three of the many scarfs awaiting glue-up. The epoxy/hardener that I'm using has over 1/2 hour of open time (shop temperature around 70) so I don't need to rush the job. The epoxy cures overnight and can be worked and handled but full strength probably takes another day or so. On the dory we used MAS resin with their blush-free slow hardener and it worked well. For the Kayak project we are using Raka 127 resin and their 350 non-blushing hardener. The main use of epoxy on the kayaks is for these scarf joints. The rest of the joints in the boats will be lashed using nylon artificial sinew. 4/16/2015 |

| Return to Kayak page | |